The product development and engineering team at Howell Foundry employ the best technologies available, paired with tried and true foundry practices to create tooling and process techniques that reliably and consistently meet the casting needs of our customers.

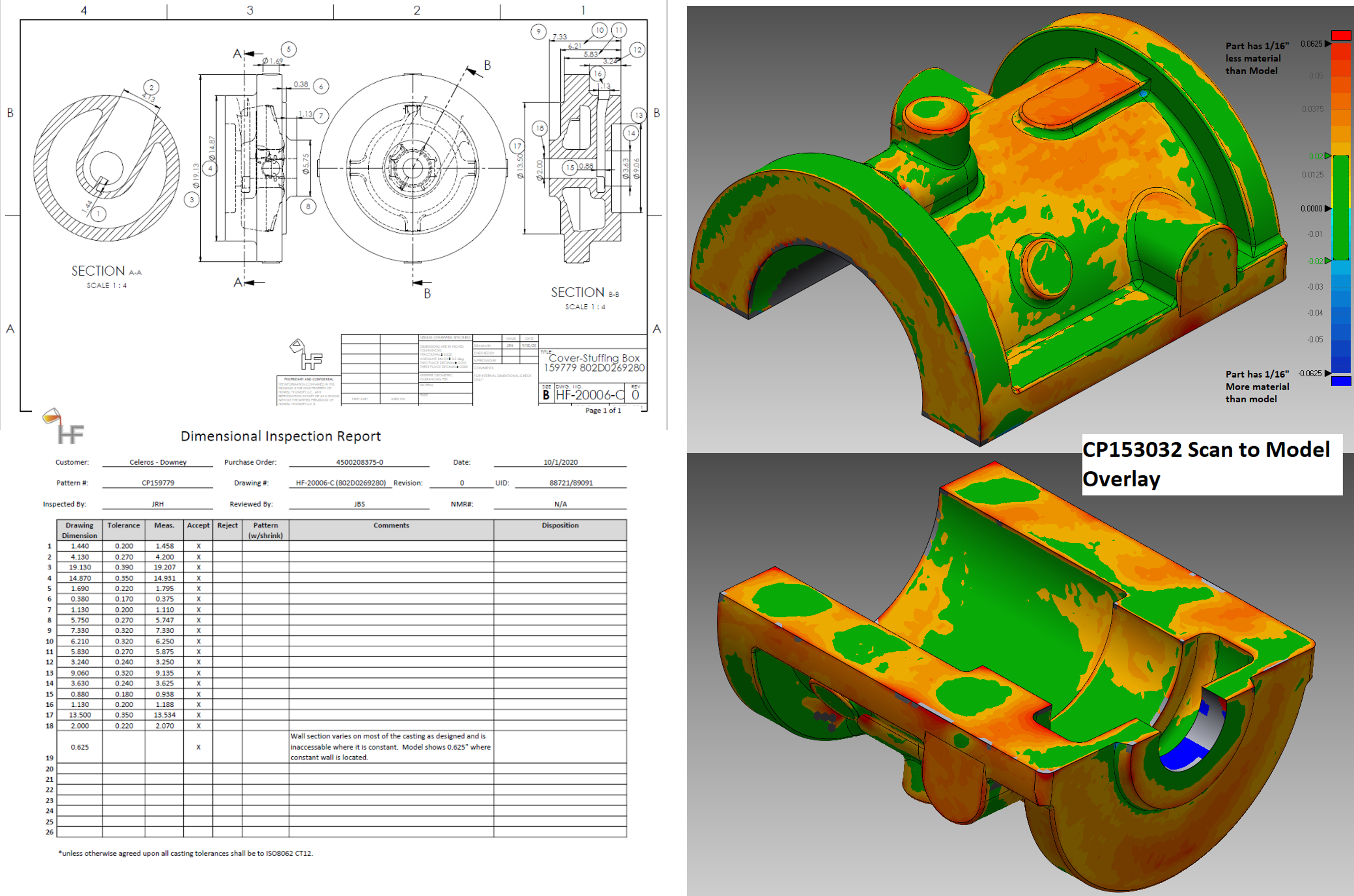

Our trained and experienced foundry experts review all designs at the beginning of the order process to ensure compatibility with accepted foundry standards. Three dimensional modeling software and analytical tools are used to engineer robust foundry procedures to produce high integrity castings.

Our first priority is to be worthy of our customers trust by offering the most dependable castings available in a timely manner.

Materials and methods

Howell Foundry procures the highest purity materials from the most reputable sources in the U.S. to provide the level of casting integrity our customers demand. This is coupled with a robust quality system developed with lean principles and repeatability in mind to make us the preferred supplier for high end cast products.

Our in-house Engineering capabilities provide the ability to service all of your casting needs.

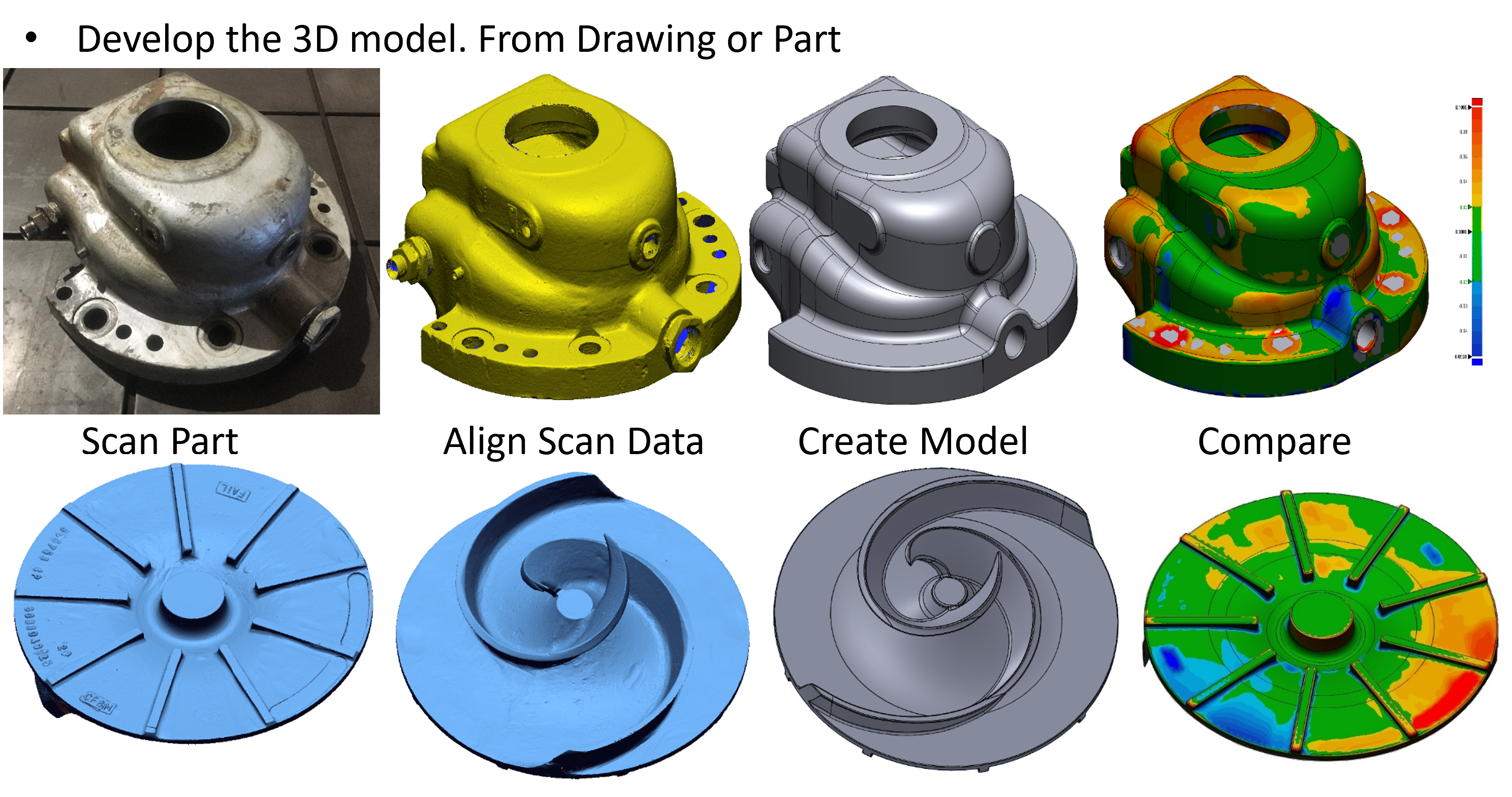

Model Development through the use of 3D Scanning Technology – we can convert your pattern or part to a reproducible digital file.

The most Modern Process Development Simulation Technology

Modern 3D Printed Mold Technology – and electric induction melting methods are used to offer a wide range of casting geometries and alloys designations.

We employ experienced NDT personnel that are qualified in accordance with SNT-TC-1A and welders that are qualified to ASME section XI of the Boiler and Pressure Vessel Code. We have the experience and the capability to handle any and all of your casting requirements including machine, fabrication and heat treatment.

| HF Alloy | Grade | ASTM |

| 1100 | High Chrome | A532, III, A |

| 1101 | Cast Iron, Class 30 | A48 |

| 2002 | Cast Iron, Class 40 | A48 |

| 2003 | NiHard | A532, I, C |

| 3001 | WCB | A216 |

| 3002 | WCA | A216 |

| 3003 | 4140 | A958 |

| 3004 | 4340 | A958 |

| 3005 | Grade D | SA225 |

| 4000 | HH Stainless | A297 |

| 4001 | HK40 | A351 |

| 4002 | CB7CU1 | A747 |

| 5000 | CK20 | A351 |

| 5001 | CE3MN | A890 |

| 5002 | CD4MCUN | A890 |

| 5003 | CD6MN | A890 |

| 5004 | CD3MN | A890 |

| 5006 | CA6NM | A743 |

| 5007 | CF8M | A743/744 |

| 5008 | CF3M | A743/744 |

| 5009 | CF8 | A743/744 |

| 5010 | CF3 | A743/744 |

| 5011 | CG3M | A744/744 |

| 5012 | CG8M | A744/744 |

| 5013 | CN7M | A743/744 |

| 5014 | CK3MCUN | A743/744 |

| 5015 | CA-15 | A743 |

| 5016 | A487 Grade 1 | A487 Gr.1 |

| 7000 | N3M | A494 |

| 7001 | CW12MW | A494 |

| 7002 | CZ100 | A494 |

| 7003 | Incoloy 800 | N/A |

| 8501 | Cobalt 6 | N/A |